Experts in Corrosion, Metallurgy

and Engineering

POWER

CORROSION (CONSULTANTS) LTD

| ▼Home▼ | ▼Services▼ | ►Boilers◄ | ▼Condensers▼ | ▼Turbines▼ | ▼Site Incidents▼ |

POWER CORROSION

(CONSULTANTS) LTD.

Ashby de la Zouch

Leicestershire

United Kingdom

Email: support@powerccl.co.uk

Tel: +44(0)1530 412418

Web: www.powerccl.co.uk

Last Updated: 20-Oct-20

Pitting corrosion

Feed water corrosion

This tube was damaged by oxygen pitting and poor feed water chemistry. We advised on managing the on and off-line chemistry to the correct standard whereby damage to the feed system, the boiler and other plant items ceased.

Acid dewpoint

Acid dewpoint corrosion

Caused this boiler stack to collapse. Correct design and plant operation are important to avoid such occurrences. We investigated this incident to facilitate an appropriate loss adjustment and advised on remedial action.

Chloride pitting

Acid chloride corrosion

Caused a series of tube failures in the boilers of a 500,000 tonne oil tanker. We specified a chemical cleaning procedure and a tube replacement programme to restore reliability in operation.

Caustic cracking

Caustic conditions caused scabbing and pitting of these heat exchanger tubes in a shell boiler. Attention to the correct control of boiler water chemistry is crucial in preserving the health of the waterside.

SCC

May be caused in boiler superheaters by the wrong boiler/feed water chemistry, incorrect chemical cleaning procedures and/or boiler malfunction. SCC is one of our specialities and in this case we identified the cause and the method of prevention.

Pitting

Corrosion fatigue

This heat exchanger tube taken from a shell boiler was pitted by dissolved oxygen in the feed water. This problem may occur when the feed is not fully de-oxygenated. In this instance we identified the root cause and recommended improvements in the mechanical and chemical treatments to avoid a recurrence.

High heat flux

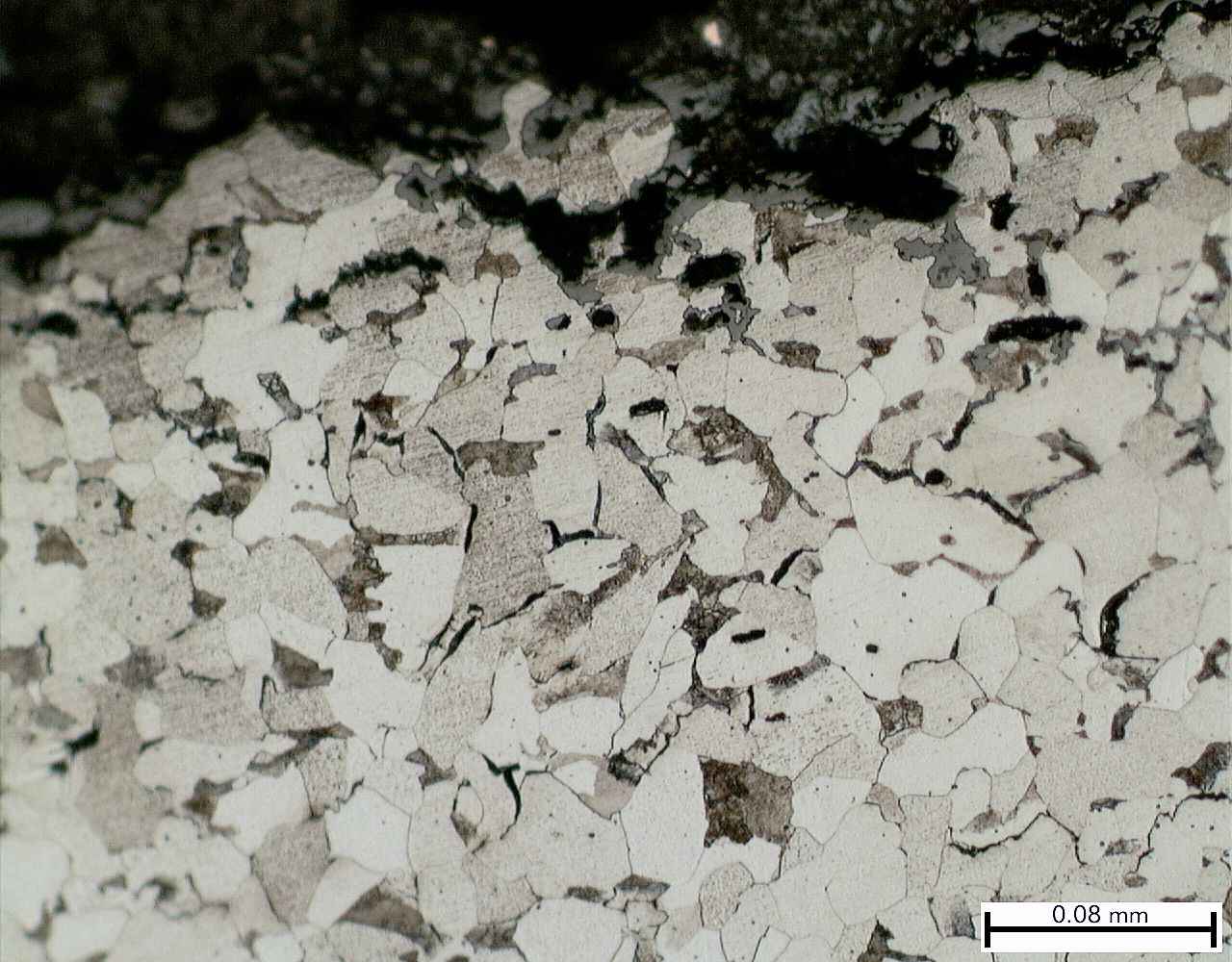

Spheroidisation

Overheating of heat exchange tubes can have many causes. Incorrect design (too small area/too high heat flux), poor water or steam circulation, surface deposits or corrosion and flame impingement are but a few. This micro-section relates to a boiler wall tube scabbed by corrosion, over heated and showing creep cracking. We can identify causes and advise on methods to avoid recurrence